3D printing research has made it possible to create precise tablet structures that can be easily modified by changing the surface curvature and control the rate of drug release.

To modulate drug release, researchers developed 3D-printed tablets with surface topography controlled by mathematical functions.

They emphasized that a common challenge in drug delivery using 3D printing is achieving precise control of the drug release profile.

“The ability to predict dissolution curves based on tablet structure, and vice versa, has promising potential for applications of 3D printing in tablet design and pharmaceuticals,” the authors explain. I’m doing it.

Several tablets with different shapes and parabolic depths were developed to allow evaluation of the effect of surface curvature on drug dissolution, the paper reported.

Main research results

The study results demonstrated that the tablet surface topography can be precisely controlled to “effectively tune the drug release profile and increase patient compliance and therapeutic efficacy.”

For example, the authors explained that formulations with the highest surface curvature “showed the fastest drug release, achieving complete release within 4 hours.”

Enhanced tablet design for optimal drug release

“The ability to predict dissolution curves based on tablet structure…provides promising prospects for the application of 3D printing in tablet design and pharmaceuticals.”

Based on its high solubility properties, Wang Others. Acetaminophen (APAP) was used as a model drug in this formulation study.

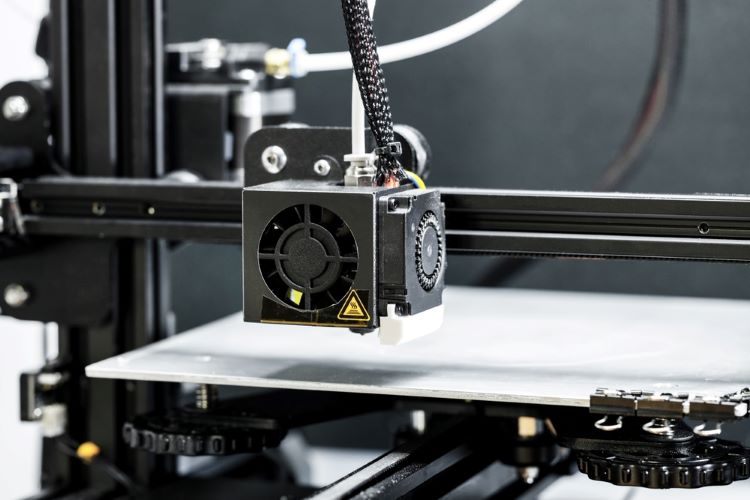

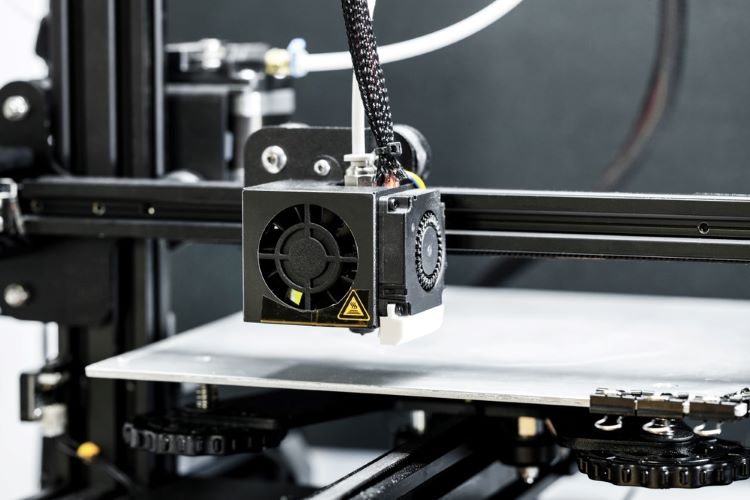

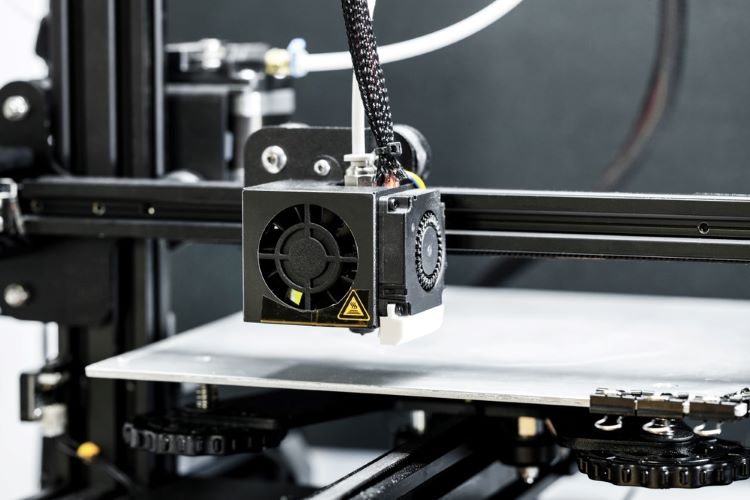

The research team used hot melt extrusion and fused deposition modeling 3D printing to create a personalized drug delivery system fabricated from thermoplastic polymers.

The authors state that the excipient matrix material chosen for the tablets was PVA, as the dissolution process was intended to be completed in “a few hours rather than over 20 hours.” [hours]”.

In terms of design, the printed tablets were manufactured with “100% packing density.” It added that this means “relatively slow dissolution rates” compared to tablets with lower packing densities.

Therefore, according to the king, Others.their approach in research addresses the “diverse demands of pharmaceutical manufacturing.”

They concluded that their new approach “represents a major advance in personalized medicine by providing a highly reproducible and adaptable platform to optimize drug delivery.”

This paper is pharmaceutical research.